|

|

Modular wastewater treatment plants "BRAVO" with membrane bio-reactor

Modular treatment plants of full operational readiness for wastewater of objects with highly bacteriological and chemical danger of its contamination.

Modular wastewater treatment plants "BRAVO" with membrane bio-reactor (further MBR) which is ready for installation on site with minimum civil works needed to prepare site for installation.

These modular plants assembled in 20 feet sea container are designed to treat even wastewaters with special requirements to filtrate quality, concerning chemical and bacteriological indicators, while discharging into the environment or municipal sewers.

Modular treatment plants "BRAVO" can be used for treatment of standard domestic wastewaters as well as for treatment of wastewaters from infectious departments of hospitals and other medical facilities. This universality is reached by usage of Mitsubishi Rayon hollow fiber membranes SUR234LB elements assembled in modules with membranes area up to 210 m2. Modular WWTP capacities are: 25 m3/day (105 m2 of membranes) or 50 m3/day (210 m2 of membranes)

Modular treatment plants "BRAVO" can be used for treatment of standard domestic wastewaters as well as for treatment of wastewaters from infectious departments of hospitals and other medical facilities. This universality is reached by usage of Mitsubishi Rayon hollow fiber membranes SUR234LB elements assembled in modules with membranes area up to 210 m2. Modular WWTP capacities are: 25 m3/day (105 m2 of membranes) or 50 m3/day (210 m2 of membranes)

Our cooperation and experience exchange with research centers and the world's leading wastewater treatment equipment allows us to solve problems of wastewater collection and treatment in complex.

Specialists of scientific-engineering center "Potential-4" are using the latest achievements of scientific and technical progress in wastewater treatment and sludge handling.

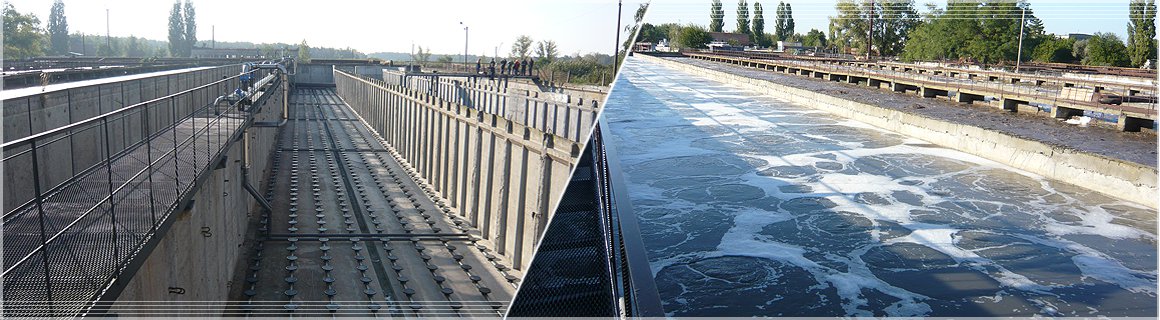

Membrane bioreactor technology (MBR), that is implemented in sea container as modular unit combines the processes of biological wastewater treatment provided by aerobic microorganisms of active sludge and separation of treated water from the active sludge by ultrafiltration membranes.

Aeration is carried out by air blowers that feed air to submersible diffusers that together are aeration system. Amount of air that had to be fed depends on number of modules installed. As suspended solids (active sludge) do not go out from the system on the lighting stage, there is full hydraulic stay-time control of wastewaters and sludge concentration control in bio-reactor, also, there is possibility to control age of active sludge.

System allows you to change the parameters of the biological reactors radically – to accumulate high concentrations of active sludge in the reactor, including slow-growing types of microorganisms(nitrifying agents, microorganisms that is able to oxidize bio-resistant compounds); to increase the age of active sludge at high hydraulic loads on the bioreactor (little residence time of initial water). Detention of suspended solids of initial wastewater in bioreactor prolongs contact with microorganisms untill complete biological destruction. Thus, biocenosis adapts well to fluctuations in the concentrations of contaminants in the initial wastewater and they are independent from the sedimentation characteristics of the active sludge. As a result it increases the stability of the system.

System allows you to change the parameters of the biological reactors radically – to accumulate high concentrations of active sludge in the reactor, including slow-growing types of microorganisms(nitrifying agents, microorganisms that is able to oxidize bio-resistant compounds); to increase the age of active sludge at high hydraulic loads on the bioreactor (little residence time of initial water). Detention of suspended solids of initial wastewater in bioreactor prolongs contact with microorganisms untill complete biological destruction. Thus, biocenosis adapts well to fluctuations in the concentrations of contaminants in the initial wastewater and they are independent from the sedimentation characteristics of the active sludge. As a result it increases the stability of the system.

The «cutoff» of microorganisms of active sludge on membranes allows cultivation of special microorganism’s strains, that are resistant to the action of organic substances and disinfectants. Disinfectants, that effect ruinously on the bacteria in active sludge on the conditions of flow treatment systems, are successfully degraded in the bioreactor without causing a loss to the adapted micro flora, and do not hinder the process of cleaning.

Microorganisms of active sludge do not penetrate through ultrafiltration membrane, so treated by MBR system water is bacteriologically safe. Membrane bioreactor operates in a high biomass concentration of substantial age. While this the main energy consumption is not used for reproduction of bacteria (as it is in the classical Biotechnology), it is used to ensure viability, that causes reduction of excessive growth of the active biomass.

Washing of the membrane unit should be performed two - four times a year as a preventative measure, and also before long stoppages while seasonal operation. Thus, washing is a simple auxiliary procedure about cost and impact on the work of treatment plants. Due to the almost complete detention of microorganisms in biological systems with membrane reactor, the following parameters of biological treatment process are changing:

-

The concentration of active sludge increases (in 3-4 times in comparison with classical techniques with aeration tanks), it leads to an equivalent reduction in the volume of bioreactor tanks;

-

Complete retention of bacteria in a volume of bioreactors allows to cultivate slow-growing, but effective water treatment types of bacteria;

-

Reduction of the growth of microorganisms and the quantity of active sludge excess, which is required to take off from the bioreactor (2-3 times in comparison with classical techniques with aeration tanks);

-

Improvement of quality of wastewater treatment in comparison with classical techniques with aeration tanks. And it does not require secondary settlers and filters for aftertreatment;

-

Disinfection of treated wastewater;

-

Reliability and high efficiency of wastewater treatment from suspended solids because emergencies related to exposure to treated water sludge are impossible.

| ¹ | Type and size of treatment plant | Dimensions L õ W õH |

Daily average performance (m3/day) | Peak flow (up to 3 hours, m3/hour) |

|---|---|---|---|---|

| 1 | «BRAVO-25» | 20’ container 6058 õ 2438 õ 2591 |

25 | 2 |

| 2 | «BRAVO-50» | 20’ container* 6058 õ 2438 õ 2591 |

50 | 8 |

| 3 | «BRAVO-75» | 40’container 12192 õ 2438 õ 2591 |

75 | 10 |

| 4 | «BRAVO-100» | 40’ container** 12192 õ 2438 õ 2591 |

100 | 16 |

* - arrangement as a storage / denitrifying tank, reinforced concrete V = 25 ì3

** - arrangement as a storage / denitrifying tank, reinforced concrete V = 50 ì3

Ultrafiltration. Separation (filtering) of the active sludge from the biologically treated wastewater in "BRAVO" with MBR is provided by submersible in the nitrifying bioreactor, hollow fiber ultrafiltration membranes. Sludge mixture is filtered through a membrane (from the outside to the inside) due to discharge that is generated inside the fibers by suction pump.

Confirmed operational lifetime of membrane elements Sterapore SUR234L, that are produced by Mitsubishi Rayon Co., Ltd (Japan), is at least 7 years. Decontamination scheme in " BRAVO " with MBR is a three-stage. The first stage is detention of 99 % of the microorganisms on the ultrafiltration membrane module , the second stage is desinfection with UV lamps with a wavelength of 256 nm. UV - disinfection of water treated in MBR is very effective because of the high transparency of the filtrate from ultrafiltration membranes. In this case, the main goal of the UV- disinfection is destruction of viruses that has size less than pore size. The third stage (if necessary) - finishing disinfection with hypochlorite or with another disinfectant.

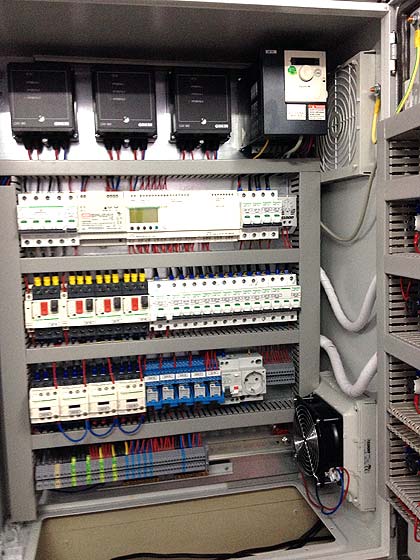

In order to reduce construction time and to ensure rapid commissioning, we suggest delivery of proposed modular wastewater treatment plant of full operational readiness in the form of a block - box with transport dimensions of standard 20’ (or 40’) container. The container should be mounted on the monolithic slab that is made of reinforced concrete.

|

|