|

|

Dissolved Air Flotation

1. Product Description:

Dissolved air flotation system for wastewater treatment is mainly for solid-liquid or liquid-liquid separation. Large sum of micro bubbles produced by dissolving and releasing system adhere to solid or liquid particles with same density as waste water to make the whole float to the surface thus achieve the aim of solid-liquid or liquid-liquid separation.

2. Application:

As a waste water process, DAF is widely used in sewage treatment and water purification enginnering. This equipment is suitable for:

a. Increase effluent recycling and fresh water reusing in paper and pulp.

b. Removal of heavy metal ions.

c. Separation of oil refinery effluent.

d. Removal of tannery wasteeater.

e. Removal of chromaticity and impurities in printing and dyeing wastewater.

f. Solid-liquud separation of sewage and membrane after all kinds of bio-treatment.

g. Sludge concentration ( capacity: 20%-30%, except the dedicated device which can be designed according to the requirements).

3. Features:

-

1. Large capacity, high efficiency and small occupying space.

-

Compact structure, easy operation and maintenance.

-

Silt expansion elimination

-

Aerate to the water while air floating, it has an obvious effect to the elimination of active agent and foul smell in water. Meanwhile, the increased dissolved oxygen provides a favorable condition to the follow-up process.

-

It can achieve the best effect in adopting this method when disposing the water with lower temperature, lower turbidity and more algae.

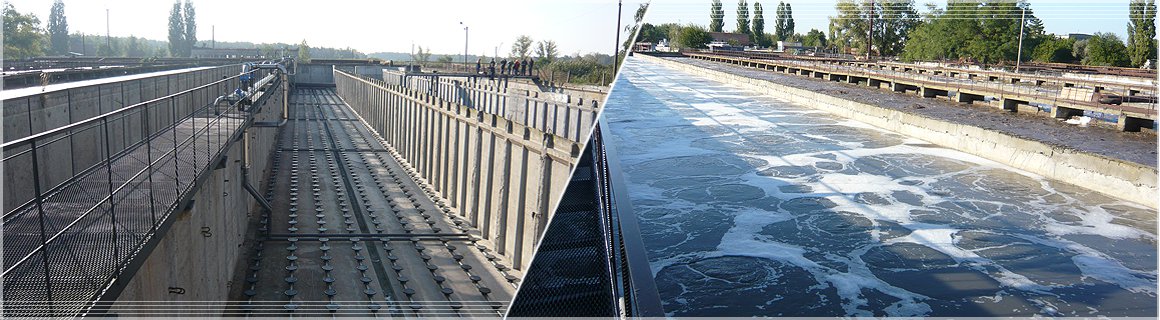

4. Product Presentation:

|

|

|

3. Main Technical Parameters

|

Model |

Capacity ( m3/h) |

Dissolved Air Water Volume (m3/h) |

Main Power ( kw) |

Aerated Motor (kw) |

Skimmer (kw) |

Total Power (kw) |

|---|---|---|---|---|---|---|

|

PQF-3 |

2-3 |

0.5-1 |

0.75 |

0.55 |

0.37 |

1.67 |

|

PQF-5 |

3-5 |

1-2 |

1.1 |

0.55 |

0.37 |

2.02 |

|

PQF-10 |

5-10 |

2-3 |

1.5 |

0.75 |

0.37 |

2.62 |

|

PQF-15 |

10-15 |

3-5 |

2.2 |

0.75 |

0.37 |

3.32 |

|

PQF-20 |

15-20 |

5-7 |

2.2 |

0.75 |

0.37 |

3.32 |

|

PQF-30 |

20-30 |

6-10 |

3 |

0.75 |

0.37 |

4.12 |

|

PQF-40 |

30-40 |

10-15 |

5.5 |

0.75 |

0.37 |

6.62 |

|

PQF-50 |

40-50 |

15-18 |

7.5 |

1.5 |

0.37 |

9.37 |

|

PQF-60 |

50-60 |

18-20 |

7.5 |

1.5 |

0.37 |

9.37 |

|

PQF-70 |

60-70 |

20-25 |

11 |

1.5 |

0.55 |

12.87 |

|

PQF-80 |

70-80 |

25-30 |

11 |

2.2 |

0.55 |

12.87 |

|

PQF-100 |

80-100 |

30-35 |

15 |

2.2 |

0.55 |

17.75 |

|

PQF-120 |

100-120 |

35-50 |

15 |

2.2 |

0.55 |

17.75 |

|

PQF-150 |

120-150 |

50-60 |

15 |

2.2 |

0.55 |

17.75 |

|

PQF-200 |

180-200 |

60-70 |

22 |

4 |

1.1 |

27.10 |

Note: The technical parameters above is for reference only, we reserve the right to its modification without prior notice. We also provide concrete tank body design and full set interior accessories according to users’ requirements and quality of water.

RQG Type Dissolved Air System

1. Application:

Provide high efficient and stable dissolved air water for dissolved air floatation system.

2. Features

a. Concise outline structure, small volume, lower power consumption, high efficiency, stable effect;

b. Overcome the dificulities that all kinds of conventional sedimentation clarifiers have, truly achieve the continuous “zero blocking” operation;

c. Safe and reliable electric control, high level of automation, convenient to operate;

3. Structure & Its Working Process

This syetem makes use of the principle of jet eductor. And when the working pressure is about 0.4 Mpa, the system dissolves air in the water through high speed flow at the shortest time.

This device condidts of dissolned air vessel, reflus pump, air compressor, frame and etc. Elcetric cabinet is set up separately.

4. Technical Parameter

|

Model |

Dissolved Air Water Volume (m3/h) |

Main Motor ( kw) |

Aerated Motor ( kw) |

Gross Weight (kg) |

Working Weight (kg) |

|---|---|---|---|---|---|

|

RQG5 |

1.5-2.5 |

1.1 |

0.37 |

680 |

720 |

|

RQG10 |

3-5 |

1.5 |

0.37 |

700 |

750 |

|

RQG20 |

7-10 |

3 |

0.75 |

720 |

800 |

|

RQG30 |

10-12 |

5.5 |

0.75 |

750 |

840 |

|

RQG40 |

12-15 |

7.5 |

0.75 |

800 |

900 |

|

RQG50 |

15-20 |

7.5 |

0.75 |

900 |

1000 |

|

RQG60 |

20 |

7.5 |

1.5 |

900 |

1000 |

|

RQG80 |

30 |

15 |

1.5 |

1000 |

1500 |

|

RQG100 |

35 |

15 |

1.5 |

1300 |

1900 |

|

RQG150 |

50 |

15 |

1.5 |

1500 |

2400 |

|

RQG200 |

65-70 |

22 |

3 |

1900 |

3100 |

|

RQG250 |

80-90 |

22 |

3 |

2500 |

4000 |

|

RQG300 |

90-110 |

30 |

3 |

3000 |

4900 |

|

RQG500 |

160-170 |

45 |

5.5 |

4200 |

6000 |

|

RQG800 |

260-270 |

75 |

11 |

6500 |

11000 |

5. Installation Dimension:

|

Model |

Dimension | ||||||

|---|---|---|---|---|---|---|---|

|

L |

B |

H |

H1 |

H2 |

D1 |

D2 | |

|

RQG5 |

1800 |

600 |

1500 |

600 |

400 |

DN32 |

DN32 |

|

RQG10 |

1800 |

600 |

1500 |

600 |

400 |

DN40 |

DN40 |

|

RQG20 |

2000 |

600 |

1500 |

600 |

400 |

DN40 |

DN40 |

|

RQG30 |

2000 |

600 |

1500 |

600 |

400 |

DN50 |

DN50 |

|

RQG40 |

2000 |

600 |

1500 |

600 |

400 |

DN65 |

DN65 |

|

RQG50 |

2500 |

800 |

1800 |

800 |

400 |

DN65 |

DN80 |

|

RQG60 |

2500 |

800 |

1800 |

800 |

400 |

DN65 |

DN100 |

|

RQG80 |

2500 |

800 |

1800 |

800 |

400 |

DN80 |

DN125 |

|

RQG100 |

2600 |

800 |

1800 |

800 |

400 |

DN80 |

DN125 |

|

RQG150 |

2600 |

1200 |

2100 |

1000 |

500 |

DN100 |

DN125 |

|

RQG200 |

3000 |

1400 |

2700 |

1200 |

640 |

DN125 |

DN200 |

|

RQG250 |

3200 |

1600 |

2700 |

1200 |

640 |

DN150 |

DN200 |

|

RQG300 |

3500 |

1600 |

2800 |

1200 |

540 |

DN200 |

DN200 |

|

RQG500 |

3800 |

1800 |

3000 |

1400 |

540 |

DN200 |

DN200 |

|

RQG800 |

4000 |

1800 |

3200 |

1400 |

675 |

DN250 |

DN250 |