|

|

Flotators, separators, rotary screens, channel screens

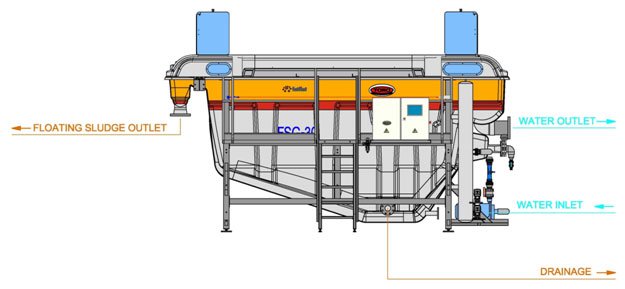

FatflotŪ Grease Separator

Grease separator FatflotŪ equipment developed by Toro Equipment is designed for the optimum treatment and separation of fat in wastewater.

The equipment is manufactured in GFR, AISI304 steel and PP.

The wide variety of grease separator fatflot FSG products enables the user to treat different ranges of water discharges.

All grease separators feature:

- Lamelar system.

- Recirculation system in PP and stainless air-saturation container.

- Several possibilities in the recirculation circuit for adapting to the clients requirements, including ball, SCP pump or Batch Pressurization System (BPS).

- Scraping system.

- Emergency shutdown and security systems.

- Control and air-injection pneumatic circuit.

- Clamps in compliance with the standards.

- Height regulating and leveling system (-100 mm).

Specification

Medium-sized equipment in the FSG range, suitable for treating discharges between 10 and 20 m³/h.

The air pressure will be between 6-8 bars for all models.

The dimensions and product specifications might vary slightly, due to the normal development of products by the engineering department of Toro Equipment S.L.

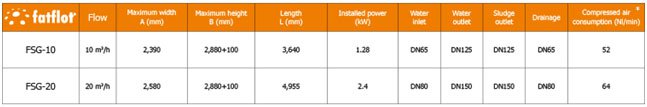

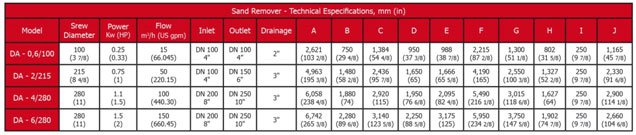

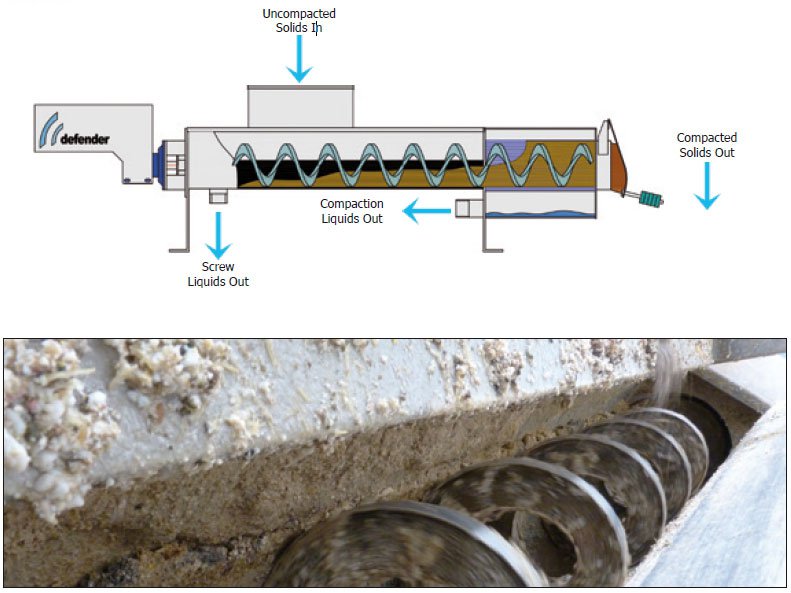

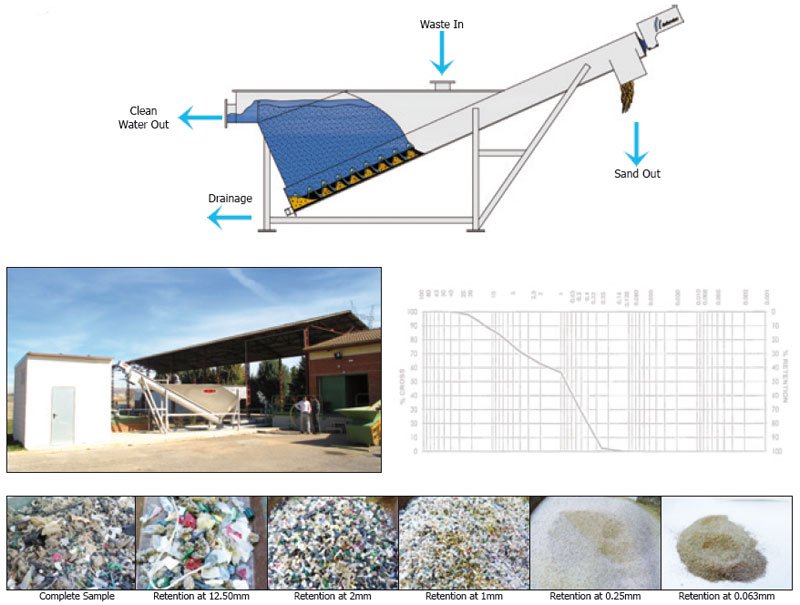

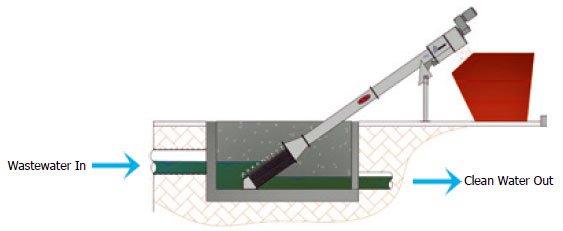

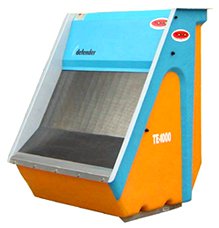

DefenderŪ Sand Remover

The Sand removers manufactured by Toro Equipment consist of sander, made of fiberglass reinforced polyester (FRP) or stainless steel, and hollow a shaft screw that contains and transports.

It forms part of the second pre-treatment phase, extracting the raw water, the suspended solids that are easy to decant such as gravel, sand and mineral particles, to prevent the channels and piping from silting up, protecting the rest of the items of equipment that make up the plant from abrasion, so there will be no overloading and blockage in the subsequent phases, and reducing the number of tasks involved where the homogenization and biological ponds are concerned.

Advantages:

- Easy to clean and maintain: The water outlet zone can be easily inspected through a hatch that opens quickly.

- There are no sealing problems: The operating device at the top of the transporter prevents airtightness problems.

- Safety: the top of the transporter tank is covered with stainless steel or fiberglass reinforced polyester (FRP).

Efficiency: It removes 97% of the sand particles down to a diameter of 0.15-0.2 mm.

Applications:

- High-efficiency water treatment plants with a high sand content:

- Beet and potato processing.

Specifications:

The specified flow rates for fine sands of 2.65 kg/dm3. It will be necessary to adjust the de-sander depending on the type and quantity of sands to remove. Consult our engineering department for further information.

The dimensions and technical specifications can vary slightly, due to the ongoing development of the products by the engineering department of Toro Equipment S.L.

While preparing your order ask for a specifications diagram.

Hydrocarbon Separator FSH DefenderŪ ŦTOROŧ

Hydrocarbon Separator FSH DefenderŪ ŦTOROŧ

Hydrocarbon separators are the separation of the remains of oils and mineral greases, fuels and other floating separation of the remains of oils and mineral greases, fuels and other floating phases present in the waters of dumping. This type of waste is mainly characterized by the presence of oils and fats minerals in concentrations ranging from 100 to 500 ppm. direct discharge or complications arising in municipal water treatment plants when it is poured into the sewer.

The maximum limit of discharge varies according to regulations, although it must be below 50 ppm.

Model range FSH:

-

FSH-2, FSH-5, FSH-10, FSH-15, FSH-20, FSH-40, FSH-80

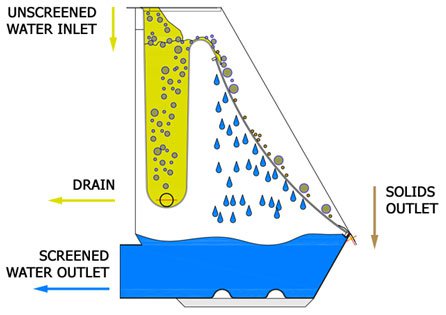

The Static Screen ŌÅ DefenderŪ ŦTOROŧ

The Static Screen ŌÅ DefenderŪ ŦTOROŧ

phases present in the waters of dumping.

Hydrocarbon separators are the

The Static Screen DefenderŪ is constructed from GRP.

It includes an AISI 316 L stainless steel filter mesh that removes the solids, leaving the filtered water free from waste, inside the static screen.

It is fitted with drainage piping and clean water outlet piping.

Channel screen AD DefenderŪ ŦTOROŧ

Designed for pre-treatment of domestic and industrial wastewater. This economic class equipment with continuous operation, which does not need energy costs. Discharge of recovered particles should be done manually. The model range includes single channel screen AD- 500 with slit size 10; 20; 30 mm.

Capacity for pure water is 55 - 70 m3 / hour.

| Model | AD 500 |

|---|---|

| Capacity (m3/h ) | |

| Slit size 30mm | 70 |

| Slit size 20mm | 60 |

| Slit size 10mm | 55 |

| Dimension | |

| Width Ņ (mm) | 644 |

| Maximum height (mm) | 600 |

| Length (mm) | 2.225 |

Reference list can be found on the official website of the company - http://www.toroequipment.com/.

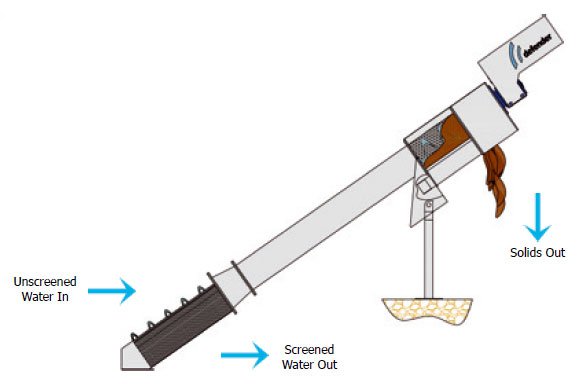

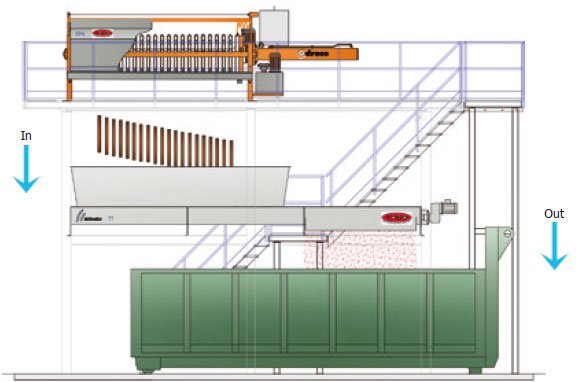

DefenderŪ channel screen conveyor

DefenderŪ channel screen conveyors manufactured by Toro Equipment are items of equipment that perform three different functions:

Screening conveying Compacting different types of solids.

Installing this pre-treatment equipment in wastewater treatment plants will help to prevent the solids of different sizes and varieties that are present in waste water or process from silting it up channels, tanks and piping. It will protect the rest of the equipment in the plant from overloading and becoming blocked.

The meshwork screens the solids. It is in the shape of half a duct and made of drilled plating (stainless steel) with 1 to 10 mm holes.

The compacting of these separate solids enables the user to minimize the moisture content and volume, thereby making it easier to manage.

These items of equipment are fitted in prefabricated channels or concrete channels. They can be made to slope at different angles according to requirements.

The DefenderŪ channel screen conveyor comes in two versions:

-

Screen Conveyor: without the compactor vat.

-

Compacter Screen Conveyor: with the compactor vat.

Advantages:

- No obstructions.

- High transport capacity.

- It enables the user to transport a great variety of materials.

Easy to clean: The final spirals of the endless screw that is located in the channel are equipped with a brush on their outer surface that makes it possible to keep the meshwork constantly clean. A meshwork cleaning system using water jets is also provided for the compacting vat.

The endless screw is resistant to wear and tear caused by friction: the inner surface of the conveyor pipe is reinforced to prevent wear and tear.

Safety: the compacting vat is equipped with a cover at the top for inspection purposes.

Versatile.

Applications:

- Urban wastewater.

- Farming & agricultural industries.

- Food-processing industry: sugar refineries, meat processing plants, chemical industry, paper mills, etc.

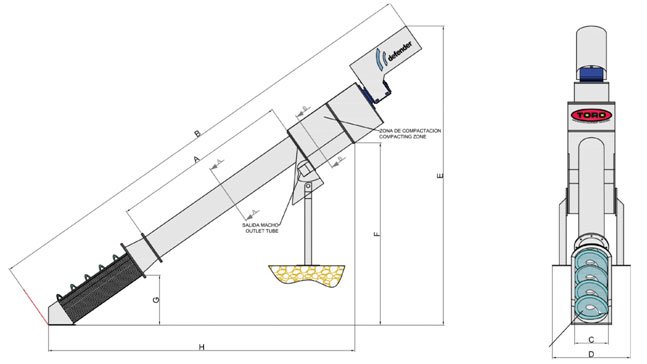

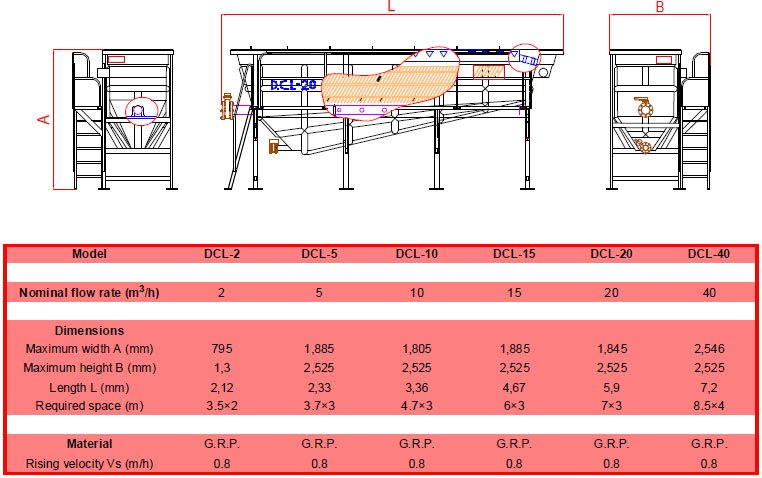

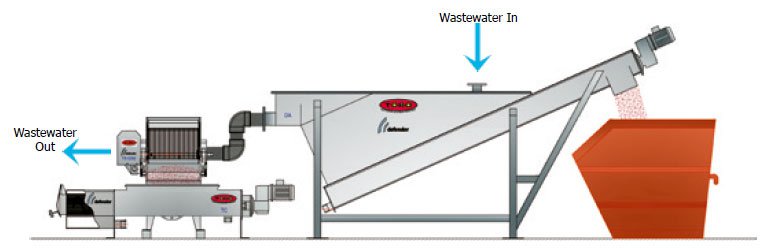

The DefenderŪ Screw Compactor

The DefenderŪ Compactor Screw by Toro Equipment is a compact piece of equipment that that performs several functions in the process of removing the solids coming from urban and industrial treatment plants, as well reducing their moisture content and their volume.

The Transportation Dehydration Compaction of solid waste (minimizing their volume) DefenderŪ compactors are pieces of equipment made of stainless steel AISI 304 or AISI 316 and are applied particularly to the treatment of solids coming from screening and grinding processes.

Advantages:

- Adaptable: it can be adapted to the installation requirements.

- High performance.

- Easy to install: it does not require any civil works or large spaces.

- Durability: it is designed to prevent the metal parts coming into contact with material or the waste water to be treated.

- No blockage or obstructions.

- High transporting capacity.

- It guarantees hygiene and an odorless process.

- Easily accessible.

Applications or solutions:

Pre-treatment: Screening and grinding phase.

The flow figure is for guidance only. Volume and turning speed of this screw will be extrapolated for each application in function of the type of waste to transport, inclination and degree of compaction.

The length of the unit can be adapted to meet requirements.

The dimensions and technical specifications can vary slightly due to the ongoing development of the products by the engineering department of Toro Equipment S.L.

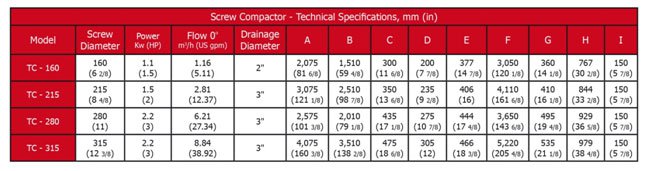

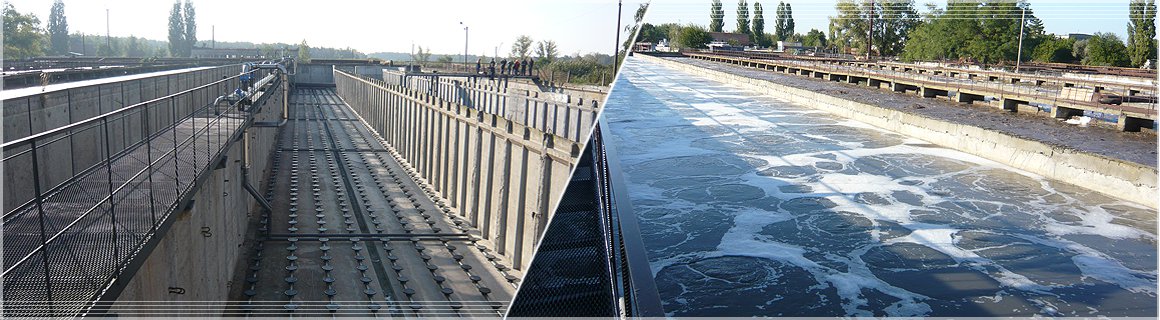

Dissolved Air Flotation unit

LAMELLAR SETTLER

The function of the lamellar settler is to remove suspended semi-heavy and heavy particles (grit, clay and lime) from the water. These elements hinder subsequent treatment by producing deposits in hydraulic conduits, piping and channels and causing abrasion to pump impellers and equipment etc.

The function of the lamellar settler is to remove suspended semi-heavy and heavy particles (grit, clay and lime) from the water. These elements hinder subsequent treatment by producing deposits in hydraulic conduits, piping and channels and causing abrasion to pump impellers and equipment etc.

Lamellar settlers are designed for the continuous separation of sediments from water and they have two basic purposes: to increase the settling area and to obtain a laminar flow.

The concept of the lamellar settler is based on the fact that the surface load (m3/m2/day) of a freefall settling tank does not depend on its depth. It is therefore possible to increase the capacity of a settling tank by dividing it, thereby creating a number of settling tanks, or by using plates inclined at a certain angle.

DESCRIPTION OF THE EQUIPMENT

The lamellar settler is an open rectangular GRP tank divided into three main chambers:

The lamellar settler is an open rectangular GRP tank divided into three main chambers:

-

Inlet chamber.

The influent flows directly into this chamber before going to the settling stage. -

Settling chamber.

The lamellar packs, made up of several GRP plates, are located in the settling chamber. The packs are arranged in parallel with an inclination angle of 60º to enable a larger settling area for the decantation of suspended solids. -

Outlet chamber.

The clean and clarified water is sent to this chamber for direct evacuation.

DESCRIPTION OF PROCESS

The influent is fed through a connection pipe to the settling chamber. Slots in the pipes located on the lower part of the lamellae allow uniform feeding of the liquid to the lamellar packs.

As the inflow passes between the plates, the solid particles slide along the inclines of the lamellae towards the bottom of the tank, while the clean water rises to the surface of the settler.

The lamellar system means that the distance travelled by a particle before settling is less than in a conventional settling tank, thereby increasing clarification capacity. A pneumatic valve at the bottom of the tank enables the settled solids to be discharged in accordance with needs. The clean clarified water in the upper part of the settling tank falls to a collection weir located along the length of the settling chamber. From this weir, it goes to the outlet chamber to be evacuated by means of a pipeline.

TECHNICAL SPECIFICATIONS

APPLICATIONS

The lamellar settler has applications in industries using materials that can be easily decanted and in potabilisation processes.

- Potabilisation plants.

- Water reuse.

- Mining industry.

- Construction materials industry.

- Industrial applications.

Pretreatment Equipment

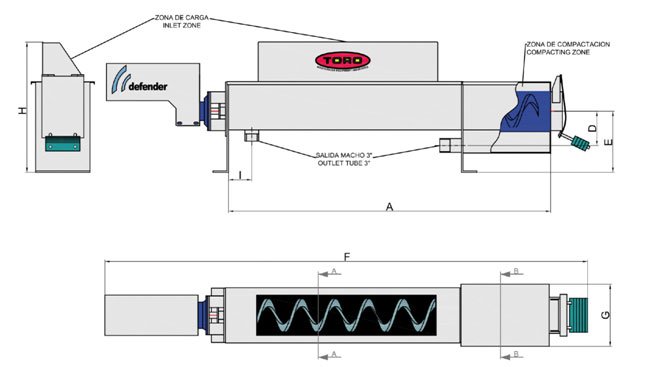

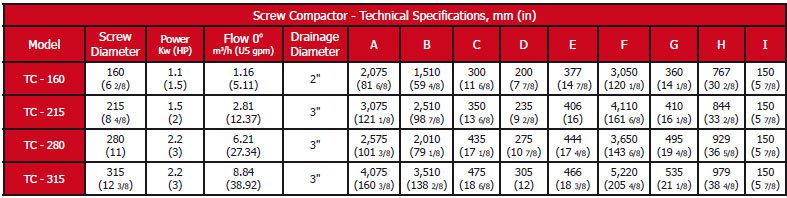

Screw Compactor · TC

Process Description:

Technical Specifications:

NOTES:

-

The flow figure is for guidance only. Volume and turning speed of this screw will be extrapolated for each application in function of the type of waste to transport, inclination and degree of compaction.

-

The length of the unit can be adapted to meet requirements.

-

The dimensions and technical specifications can vary slightly due to the ongoing development of the products by the engineering department of Toro Equipment S.L.

-

When preparing your order ask for a specifications diagram.

-

More specific figures can be found on our webpage, www.toroequipment.com.

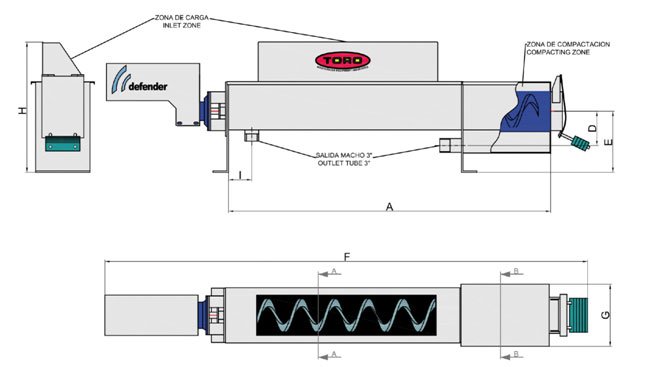

Conformity Drawing · TC DefenderŪ:

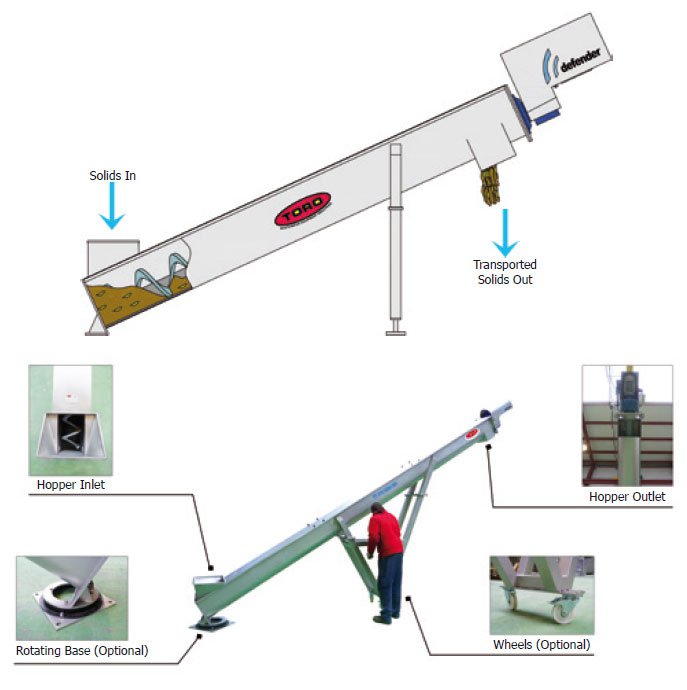

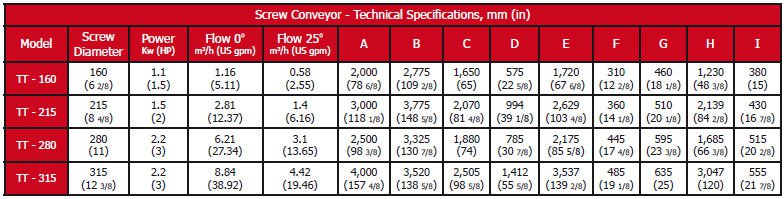

Screw Conveyor · TT

Process Description:

Technical Specifications:

NOTES:

- The flow figure is for guidance only. Volume and turning speed of this screw will be extrapolated for each application in function of the type of waste to transport, inclination and degree of compaction.

- The length of the unit can be adapted to meet requirements.

- The dimensions and technical specifications can vary slightly due to the ongoing development of the products by the engineering department of Toro Equipment S.L.

- When preparing your order ask for a specifications diagram.

- More specific figures can be found on our webpage, www.toroequipment.com.

Conformity Drawing · TT DefenderŪ:

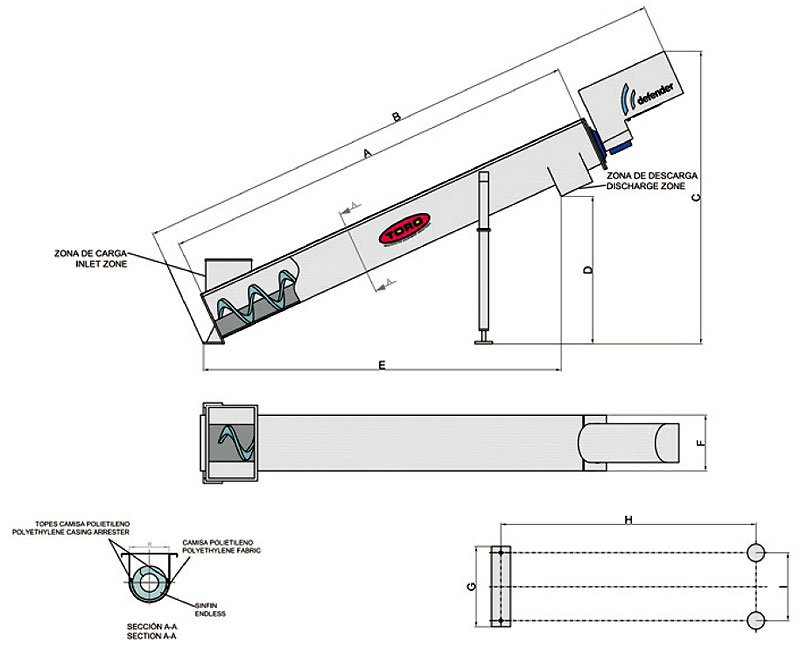

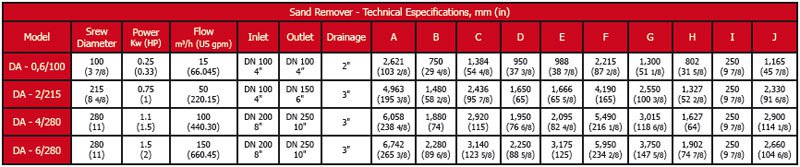

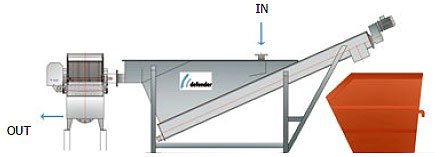

Sand Remover · DA

Process Description:

Technical Specifications:

NOTES:

- The specified flow rates are for fine sands of 2.65 kg/dm3. It will be necessary to adjust the de-sander depending on the type and quantity of sands to remove. Consult our engineering department for further information.

- The dimensions and technical specifications can vary slightly due to the ongoing development of the products by the engineering department of Toro Equipment S.L.

- When preparing your order ask for a specifications diagram.

- More specific figures can be found on our webpage, www.toroequipment.com.

Conformity Drawing · DA DefenderŪ:

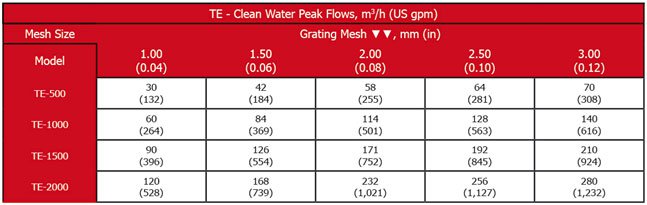

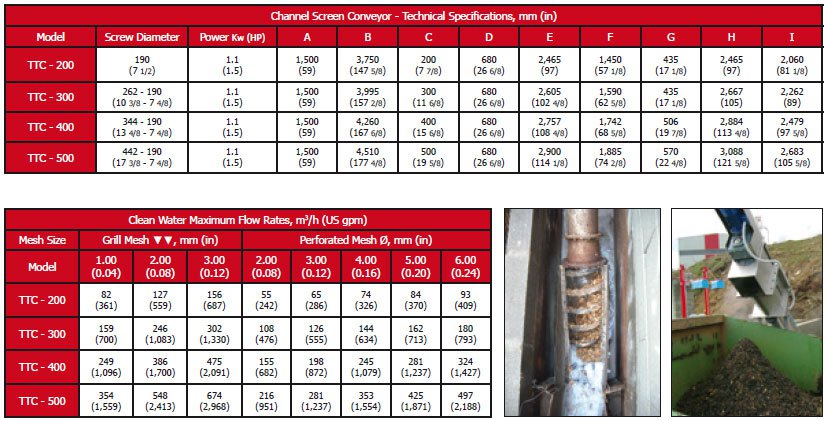

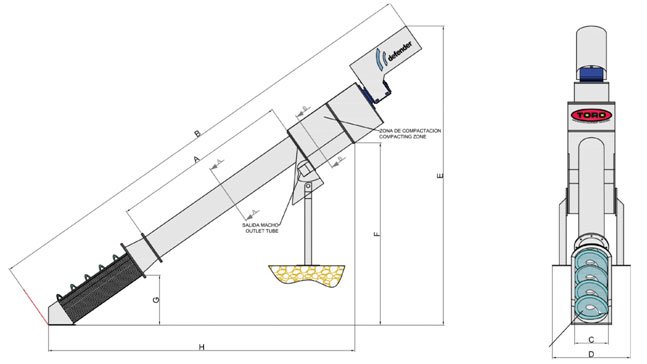

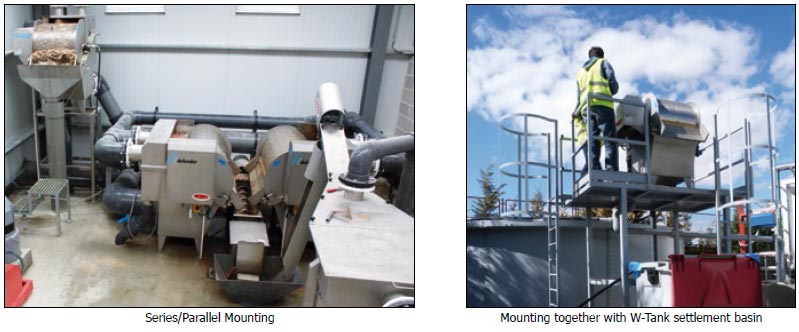

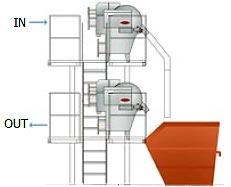

Channel Screen Conveyor · TTC

Process Description:

Technical Specifications:

NOTES:

- A reduction factor has to be applied to the specified clean water flow rates, depending on the type and quantity of solids to be removed. Enquiries to our engineering department.

- The dimensions and technical specifications can vary slightly due to the ongoing development of the products by the engineering department of Toro Equipment S.L.

- When preparing your order ask for a specifications diagram.

- More specific figures can be found on our webpage, www.toroequipment.com.

Conformity Drawing · TTC DefenderŪ:

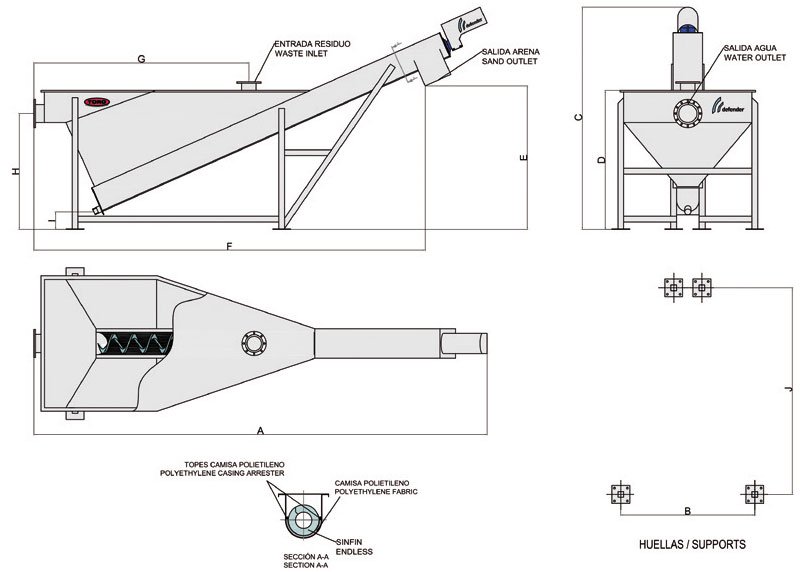

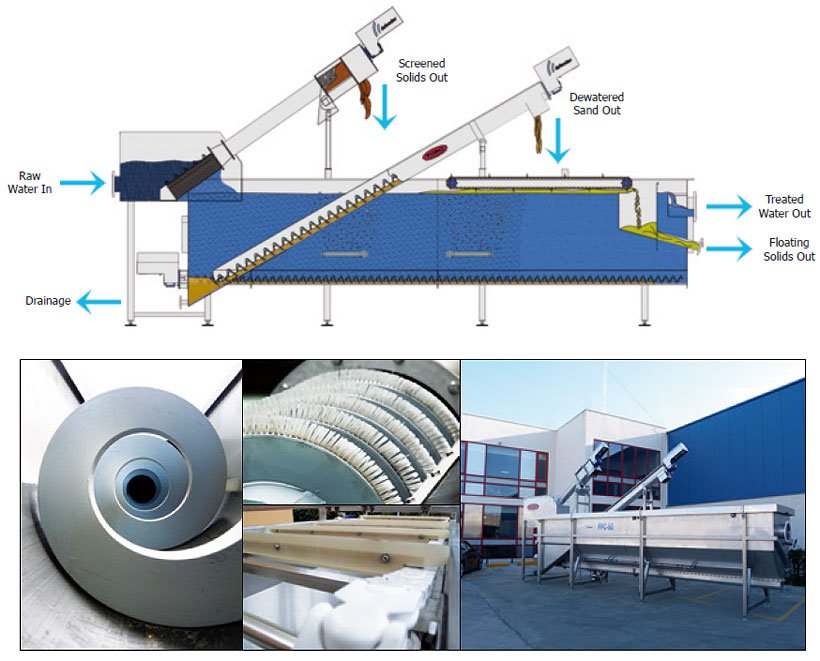

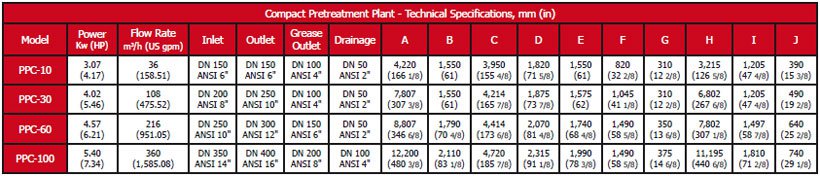

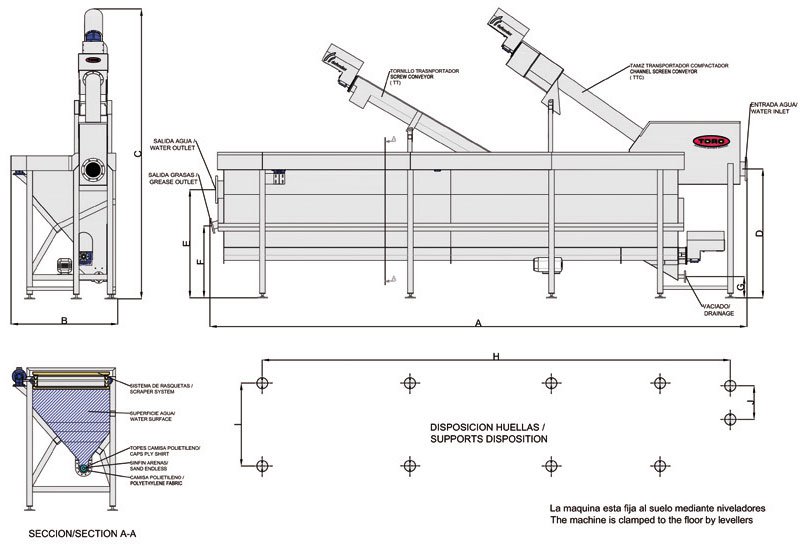

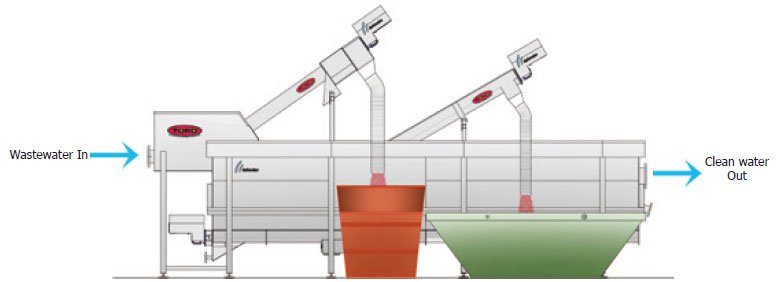

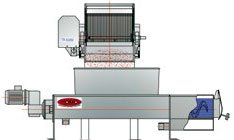

Compact Pretreatment Plant · PPC

Process Description:

Technical Specifications:

NOTES:

- A reduction factor has to be applied to the specified clean water flow rates, depending on the type and quantity of solids to be removed. Enquiries to our engineering department.

- The dimensions and technical specifications can vary slightly due to the ongoing development of the products by the engineering department of Toro Equipment S.L.

- When preparing your order ask for a specifications diagram.

- More specific figures can be found on our webpage, www.toroequipment.com.

Conformity Drawing · PPC DefenderŪ:

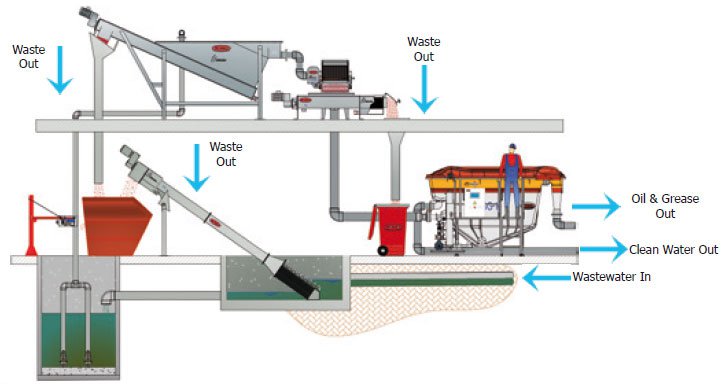

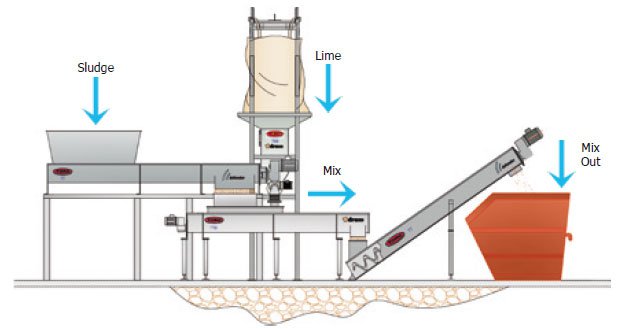

Implementations

Standard Pretreatment: TTC, DA, TR, TC and FSG

Group TT, TBB, TTM and TT:

Channel Screen Conveyor:

Screw Conveyor:

Group DA, TR and TC:

Compact Pretreatment Plant:

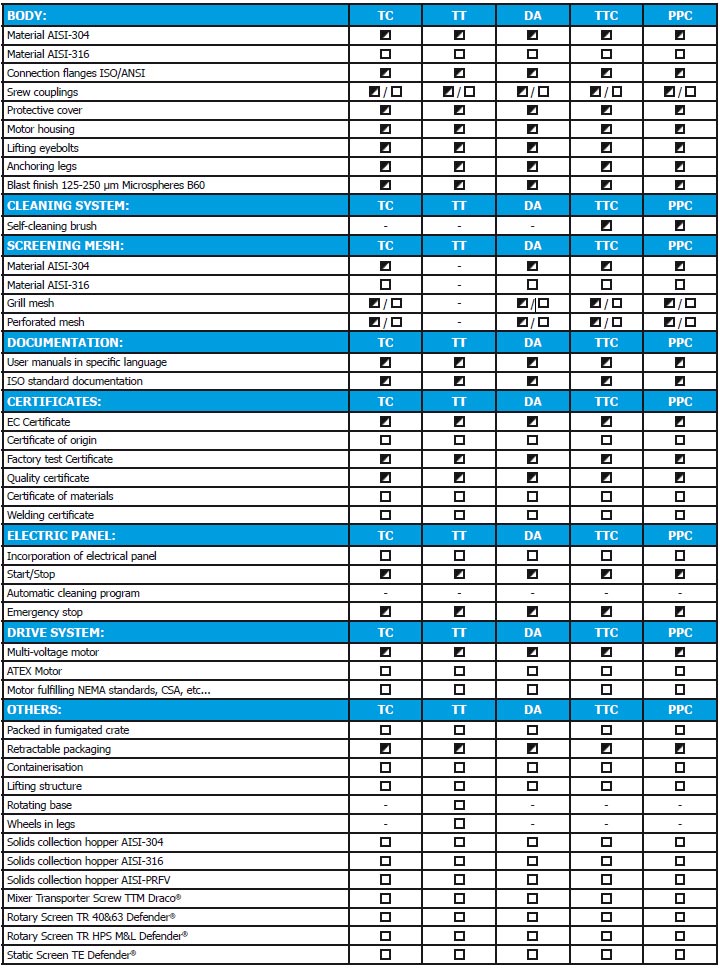

Optionals

Equipment: Standard ![]() & Optional

& Optional ![]()

NOTAS:

- The optional equipment has a surcharge. Request information and quotation.

- The ongoing development of the units can alter some of their specifications.

- You will find the latest information in www.toroequipment.com.

Characteristic

Advantages and Applications:

|

Quality and Industrial Processes:

|

|

|

Compact and Pre-mounted plants:

|

|

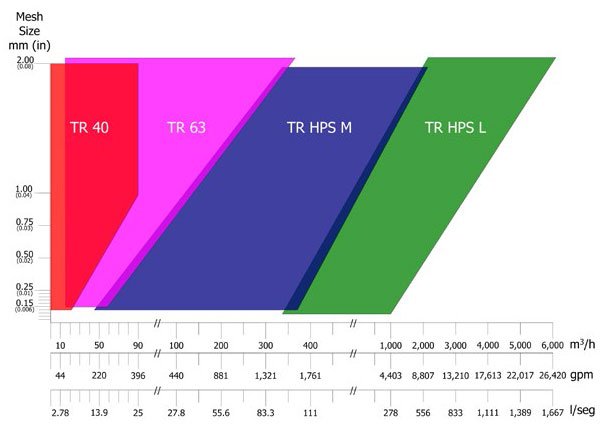

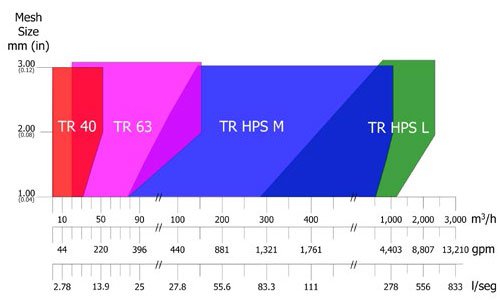

ROTARY SCREENS

DefenderŪ brand rotary screens: high performance filters for solid-liquid separation. Perfect for pretreatment of wastewater. Produced entirely by Toro Equipment SL.

TR DefenderŪ 40 and 63 Ranges, with filtering capacity five times higher than a static screen.

TR DefenderŪ HPS M and L Ranges, capable of handling four times more flow than conventional screens in its class.

Process Description

Operation:

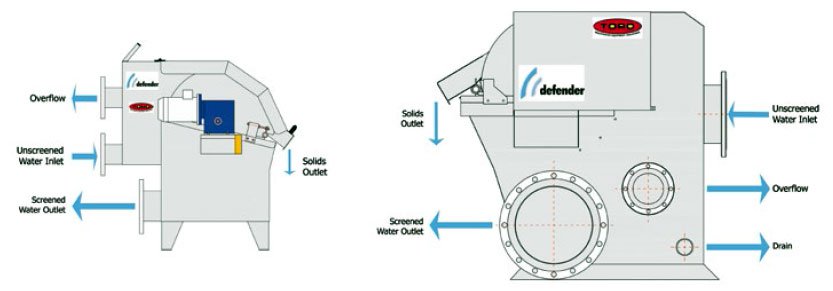

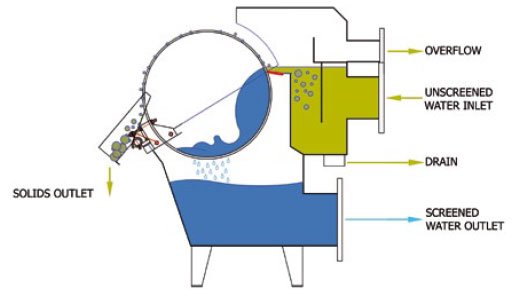

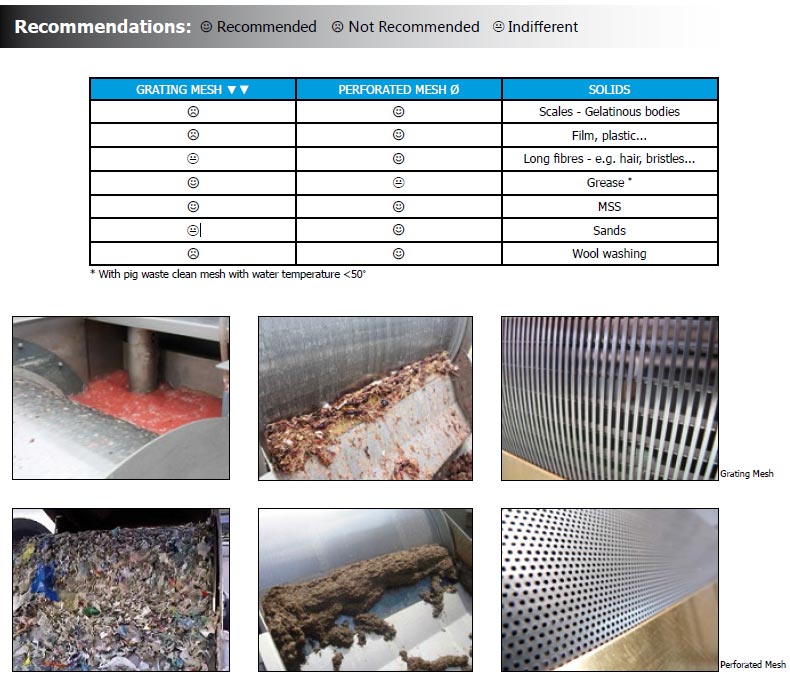

DefenderŪ Rotary Screens are pre-treatment polishing equipment in the process of removing solid-liquid waste through a filter drum formed by a grating or perforated mesh of different apertures depending on the type and amount of solids being treated.

Their task is to remove the solids carried by the water in order to avoid obstructions and mechanical problems in the plant.

They are stand-alone units with self-cleaning systems and automatic drive operation.

In municipal water they frequently permit replacement of primary clarifiers, providing elimination of coarse sands and up to percentages of 30% of grease and effluent excess. The apertures used are from 0.50 to 0.15 mm.

Simple operation:

-

The discharge to be treated enters through the flange located on the outside of the screen body, being uniformly distributed by the spillway and overflow over the drum filter.

-

The solids are retained on the drum surface while it rotates, the discharge entering through the mesh performs a self-cleaning function as it passes again through the bottom of the drum.

-

On passing through the external scraper, solids are detached from the mesh, and fall from the scraper thanks to gravity.

Description of Equipment

Equipment Parts:

FILTER DRUM, made of stainless steel by the spiral winding of a triangular section on longitudinal ribs grating mesh or a drum perforated with different diameters. The base of said triangular mesh grating or diameter coincides with the external surface of the drum. This strong, rigid assembly retains the solids on the outer surface of a size greater than the opening used and prevents the formation of clusters inside.

FILTER BODY, in which the drum filter is fixed at its front by bearings. At the rear it has an unscreened water receiving tank that distributes it in laminar flow.

CLEANING SCRAPER, which removes the solids deposited on the surface of the filter drum.

DRIVE UNIT consists of a reduction-gear motor coupled directly on the filter drum shaft providing this with a rotational movement.

SCREENED WATER RESERVOIR, is situated below the filter body and collects the filtrate which is extracted through a flanged pipe.

CLEANING SYSTEM, located inside the filter drum, fitted with jets that project water under pressure on the inner face of the cylinder to achieve complete cleaning.

Characteristics

Advantages and Applications:

- Made of stainless steel type 316 L.

- Includes safety and splash-suppression lid as a standard feature in the 40 Range.

- Emergency stop and solenoid valve for cleaning.

- Internal cleaning system with jets.

- External cleaning system with scraper.

- The equipment is guaranteed against defects in materials and workmanship under normal use and maintenance.

- Toro Equipment provides commissioning and after sales service, contact us.

- Applicable to any wastewater pre-treatment:

- Trash collection.

- Foodstuff manufacture.

- Breweries and wine cellars.

- Meat processing.

- Canneries.

- Dairies/Creameries.

- Tanneries and textile industries.

- Municipal wastewater.

- Fish processing.

- High oil content applications.

- Washhouses.

- Bio-diesel production.

Screen Range

Grating Mesh Screen:

Perforated Mesh Screen:

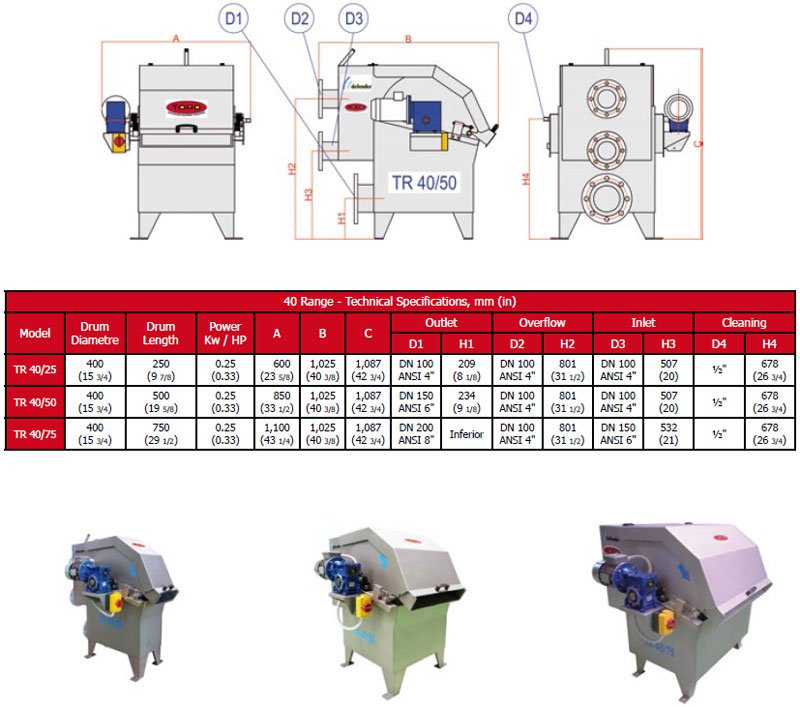

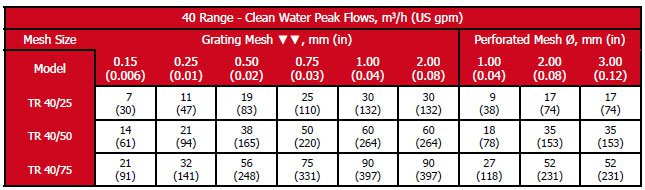

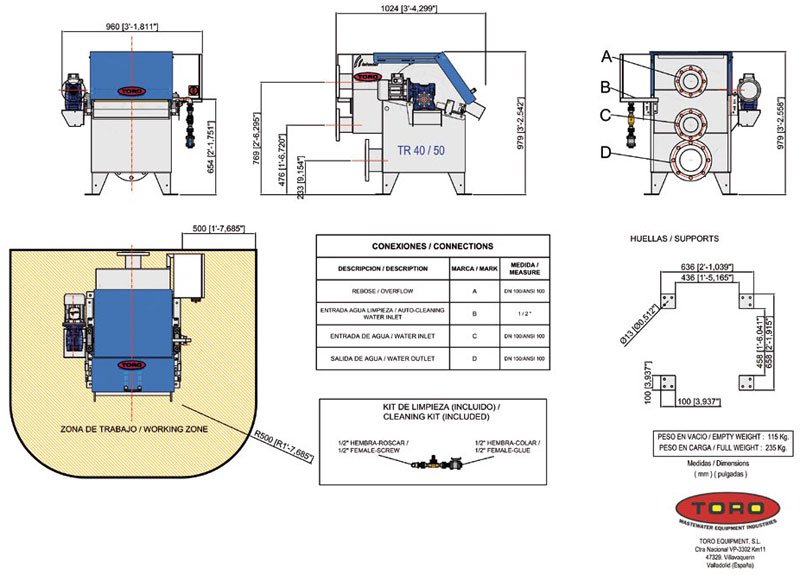

40 Range Rotary Screen Technical Specifications

NOTES:

- Flows specified for clean water. A reduction should be applied according to the type and amount of solids removed. Consult our technical department.

- The dimensions and technical specifications may vary slightly due to normal product development by the engineering department of Toro Equipment, S.L.

- Request specifications sheet when ordering.

- You can find more specific figures in our website, www.toroequipment.com.

DefenderŪ TR 40/50

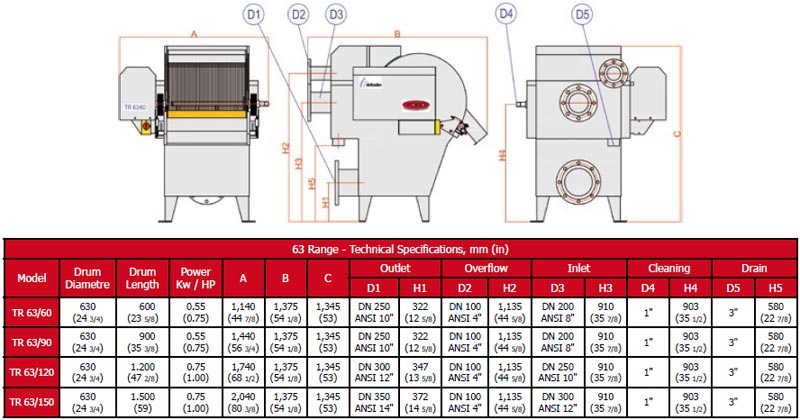

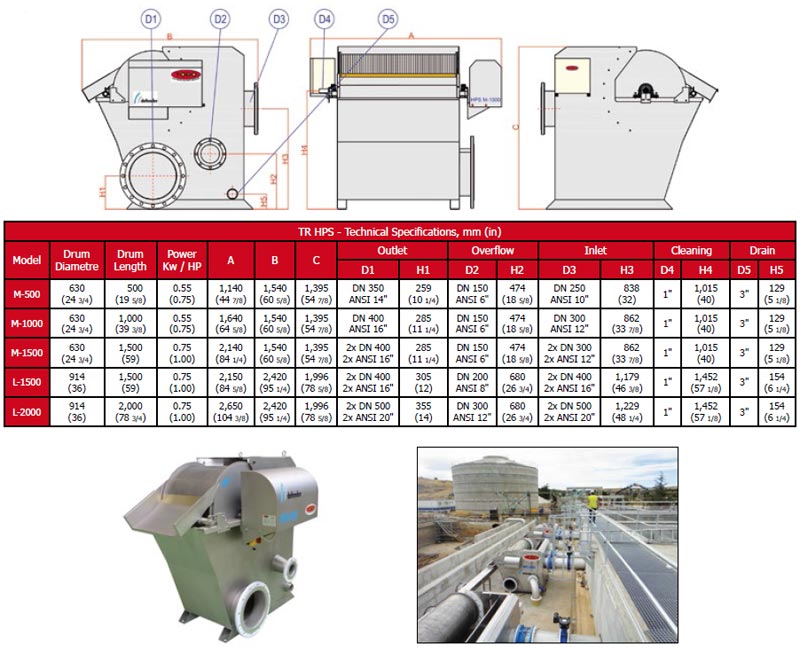

63 Range Rotary Screen Technical Specifications

NOTES:

- Flows specified for clean water. A reduction should be applied according to the type and amount of solids removed. Consult our technical department.

- The dimensions and technical specifications may vary slightly due to normal product development by the engineering department of Toro Equipment, S.L.

- Request specifications sheet when ordering.

- You can find more specific figures in our website, www.toroequipment.com.

DefenderŪ TR 63/60

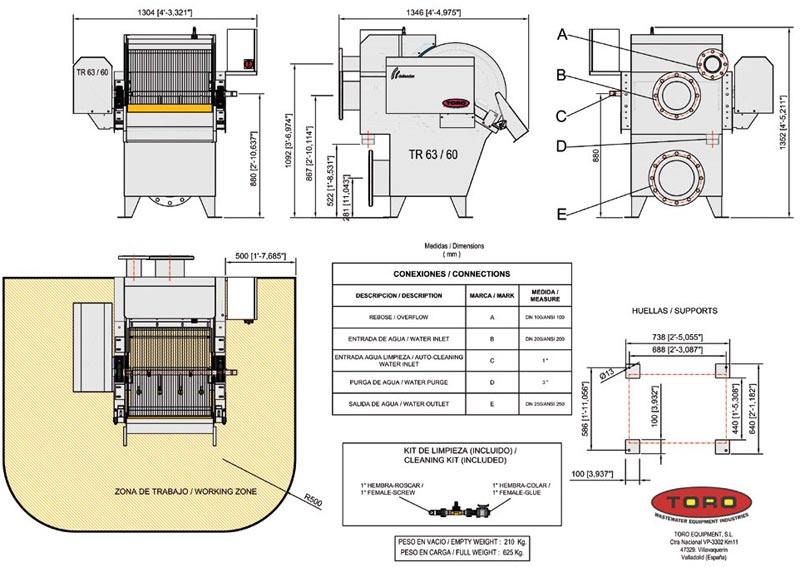

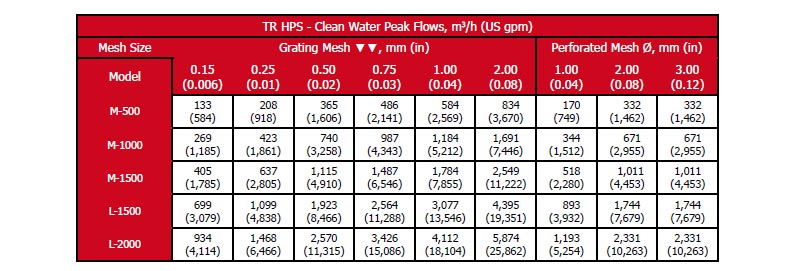

M/L Range TR HPS Technical Specifications

NOTES:

- Flows specified for clean water. A reduction should be applied according to the type and amount of solids removed. Consult our technical department.

- The dimensions and technical specifications may vary slightly due to normal product development by the engineering department of Toro Equipment, S.L.

- Request specifications sheet when ordering.

- You can find more specific figures in our website, www.toroequipment.com.

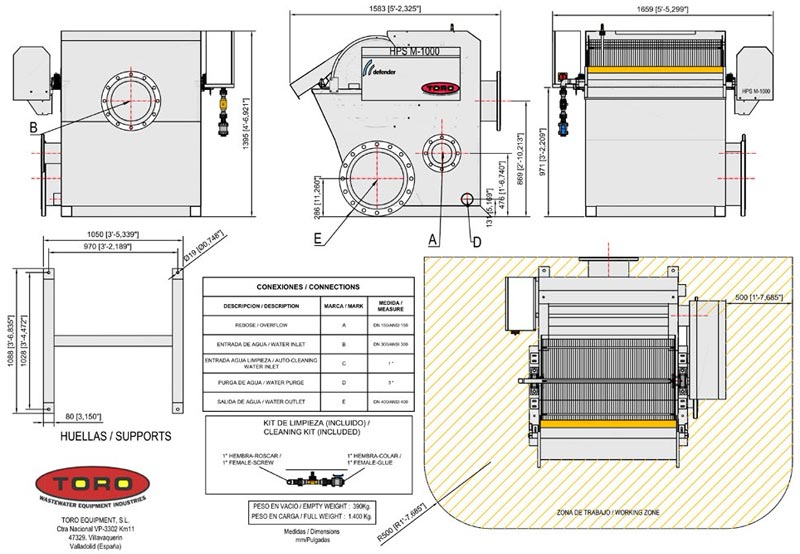

DefenderŪ TR HPS M-1000

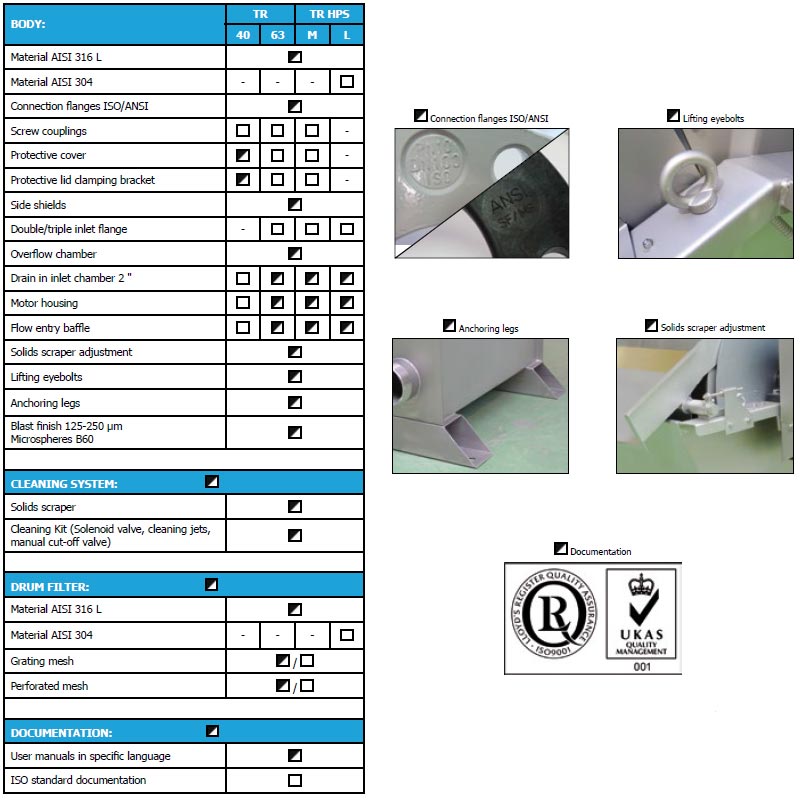

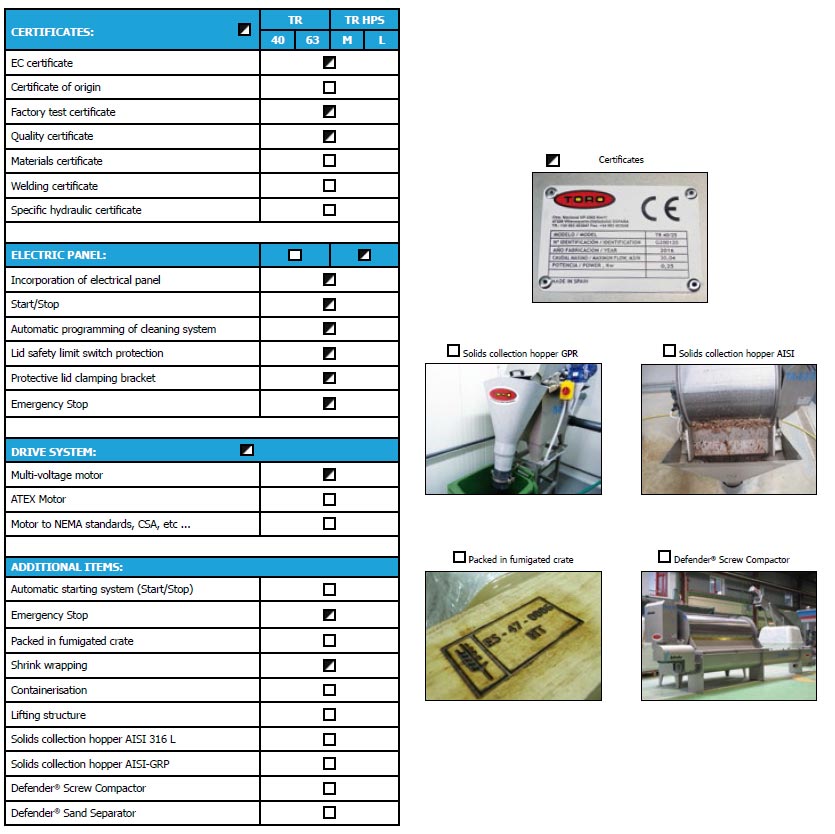

Equipment

Equipment: Standard ![]() Optional

Optional ![]()

To achieve high quality products and services, Toro Equipment has developed and implemented a Quality Management System in accordance with the UNE-EN-ISO 9001 standard, adapted to company needs and adopting continuous improvement methodology to attain business excellence.

-

The system is based on continuous monitoring of all activities undertaken in the company:

- Design

- Manufacture

- After sales service

Equipment: Standard ![]() Optional

Optional ![]()

-

The standard electric panel includes Start/Stop, limit switch to stop the drum when the protective lid is raised, securing support, emergency stop and automatic programming of the cleaning system.

- Start/Stop, start or stop the machine in the presence or absence of flow. Level sensing device that activates the machine when water for treatment is detected.

Implementation

- HPS High Capacity Rotary Screens require a minimum flow for effective operation.

- Rotary Screens in the 40 and 63 Ranges work with any flow rate up to their maximum capacity.

- The screens deliver the solids by gravity through a hopper or compactor screw for which reason it is recommended to study the installation height of the equipment for discharge, collection and processing of such solids.

|

* e.g. Upper Size 2.00 mm, Lower Size 0.25 mm |

|

|

|

|

Other Details

Compact and Pre-Assembled Plants:

-

On request, compact plants are containerised. Ask for information.

-

Plants are also available pre-assembled on a structure.

Test Pilot and Test Factory:

- Our laboratory test the water to determinate mesh size.

- The equipments are pre-assembled and tested in our factory.

Transport and Packaging:

- On request:

- Transportation of equipment in treated wooden crates.

- Palletising and plastification of equipment.

- Containerisation.

Hydrocarbon Separator FSH DefenderŪ ŦTOROŧ

Hydrocarbon Separator FSH DefenderŪ ŦTOROŧ The Static Screen ŌÅ DefenderŪ ŦTOROŧ

The Static Screen ŌÅ DefenderŪ ŦTOROŧ