|

|

Filter press

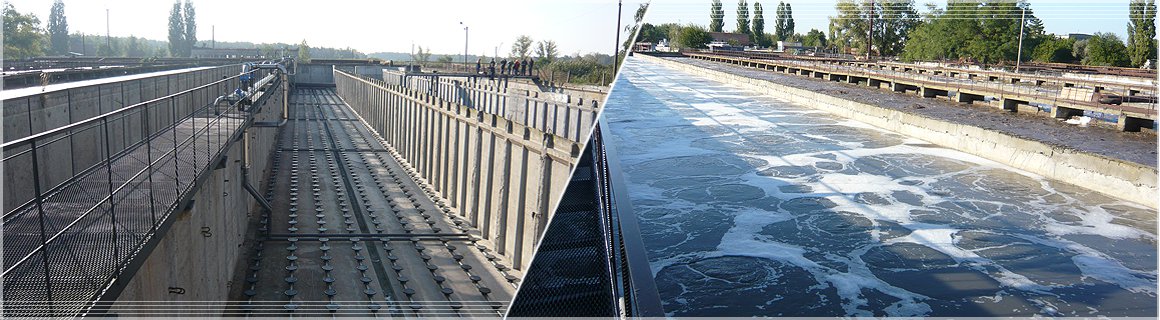

Belt Filter - press - this equipment is designed for thickening and mechanical dewatering of domestic, municipal and industrial sewage.

There are two types of filter press:

-

Rotary Drum Thickening/Dehydrating Belt Filter press

-

Gravity Belt Thickening/Dehydrating Belt Filter press

Operating Mechanism of filter-press

Step 1: The sludge flow into the filter-press with an appropriate pump system and extends along the length of the plate until all the chambers are not filled by pulp.

Step 2: Under pressure, the solids begin to settle on the surface of filter mesh, forming a primary layer of the filter sludge, called a pre-coat. This pre-coat becomes the actual filter material.

Step 3: Since the filtration continues, sludge density gradually increases. At the moment of filter cycle, dewatering phase takes the final stage to achieve maximum dryness of the sludge.

Step 4: During the next stage of the cycle, additional solids is pumped into the filter chamber to displace more liquid. This leads for drying, consolidation and compaction of sludge. This cycle usually continues until the flow of fluid to the press cannot be reduced up to zero. At this moment, that the feed pump is stopped, and the internal pressure decreases. At this moment supply pump is stopped and internal pressure decreases.

Step 5: Before unloading of filtered sludge, can be additionally washed in place at the place of remove impurities for neutralization purposes.

Step 6: With decreasing pressure of filter pressure, closing hydraulic system is actuated to retract the movable head to the fully open position. After the opening, each individual filter plate is separated from its adjacent neighbor, allows sludge to fall freely between the individual chambers. With fully mechanized shifter plates, transport speed is regulated, but an average of 6 to 8 plates per minute.

Step 7: To start the next cycle of filtration activate hydraulic closing system.

Application:

-

Sludge dewatering for different industries

-

Dewatering of sludge in the slaughter floor

-

Dewatering of sludge from municipal sewage

-

Dehydration of many kinds of algae

-

Separation of the solid and liquid phases in the processing of foods and beverages.

-

Chemical industry, mineral resource industry, etc.

-

Wastewater which contains palm oil.

Process:

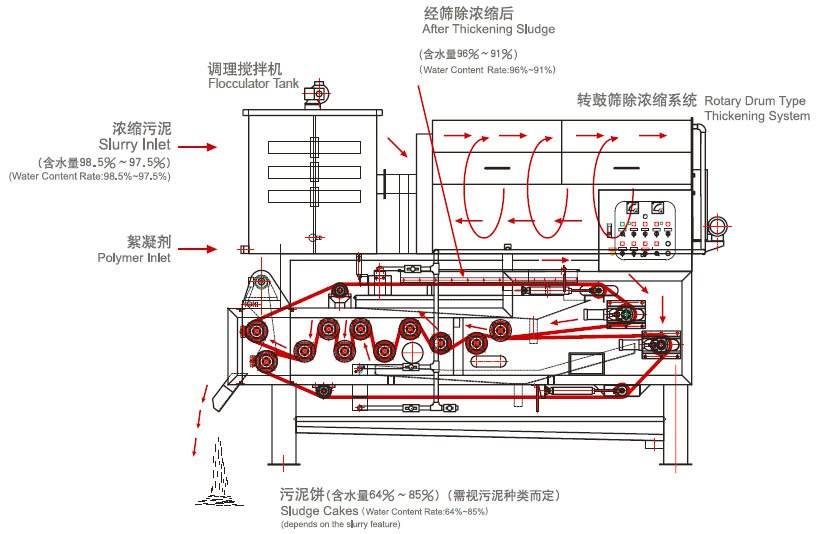

a. Rotary Drum Thickening/Dehydrating Belt Filter press

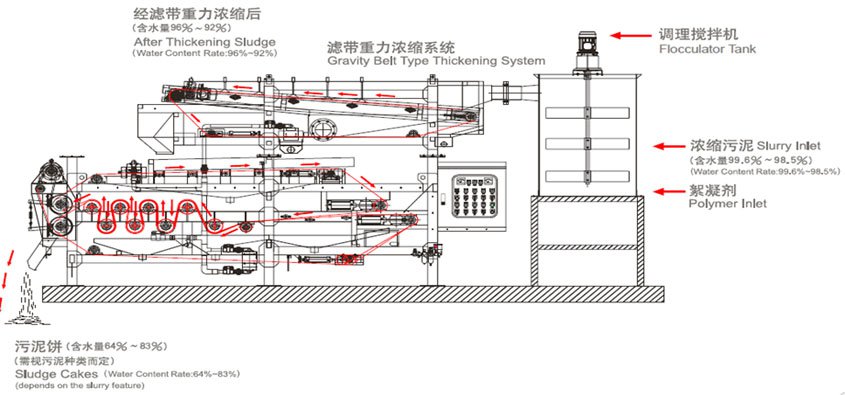

b. Gravity Belt Thickening/Dehydrating Belt Filter press

Specifications

a. Rotary Drum Thickening/Dehydrating Belt Filter press

| Model | ZDY1.0 | ZDY1.5 | ZDY2.0 | |

|---|---|---|---|---|

| Belt width (MM) | 1000 | 1500 | 2000 | |

| Productive capacity (m³/hr) Output concentration (s.s1~5%) |

6.5~10.5 | 12~20.5 | 18~30 | |

| Dried sludge (kg/hr) | 98~158 | 180~308 | 240~450 | |

| Water content in the cake (%) | 75~85 | 75~85 | 75~85 | |

| Capacity (HP) | Engine | 0.37 | 0.75 | 0.75 |

| Mixer engine | 0.37 | 0.55 | 0.75 | |

| Belt thickener | 0.37 | 0.55 | 0.55 | |

| Lower pallet for collecting filtrate | ДА | ДА | ДА | |

| External dimensions (MM) | L | 2600 | 3300 | 3450 |

| W | 1550 | 2150 | 2900 | |

| H | 2540 | 2550 | 3100 | |

| Basic dimensions (L1*W1,MM) | 2100*1330 | 2450*1860 | 2715*2420 | |

| Weight (Kg) | 1210 | 2200 | 2850 | |

b. Gravity Belt Thickening/Dehydrating Belt Filter press .

| Model / Dimensions | DNY1.0 | DNY1.5 | DNY2.0 | |||

|---|---|---|---|---|---|---|

| Belt width (mm) | 1000 | 1500 | 2000 | |||

| Low concentration | Capacity (m³/h) Output concentration (S.S. 0.4 ~ 0.8%) |

15 ~ 20 | 25 ~ 33 | 35 ~ 45 | ||

| Dried sludge (kg/h) | 60 ~ 120 | 100 ~ 198 | 140 ~ 270 | |||

| The average concentration | Capacity (m³/h) Output concentration (S.S. 0.8 ~ 1.5%) |

12.5 ~ 15 | 20 ~ 25 | 30 ~ 35 | ||

| Dried sludge (kg/h) | 100 ~ 188 | 160 ~ 300 | 240 ~ 450 | |||

| Water content in the cake (%) | 75~85 | 75~85 | 75~85 | |||

| Потребляемая мощность (kw) | Drive engine | 0.37 | 0.75 | 0.75 | ||

| Mixer engine | 0.37 | 0.37 | 0.55 | |||

| Belt thickener | 0.37 | 0.55 | 0.55 | |||

| Lower a pallet for collecting filtrate | No | No | No | |||

| External dimensions (mm) | L | 4950 | 5200 | 5400 | ||

| W | 1650 | 2150 | 2650 | |||

| H | 2800 | 2850 | 2900 | |||

| Basic dimensions L1×H1 (mm) | 4050×2300 | 4150×2350 | 4200×2500 | |||

| Basic dimensions L2×W1 (mm) | 2580×1400 | 2580×1900 | 2580×2400 | |||

| Weight (kg) | 1650 | 2150 | 2900 | |||