|

|

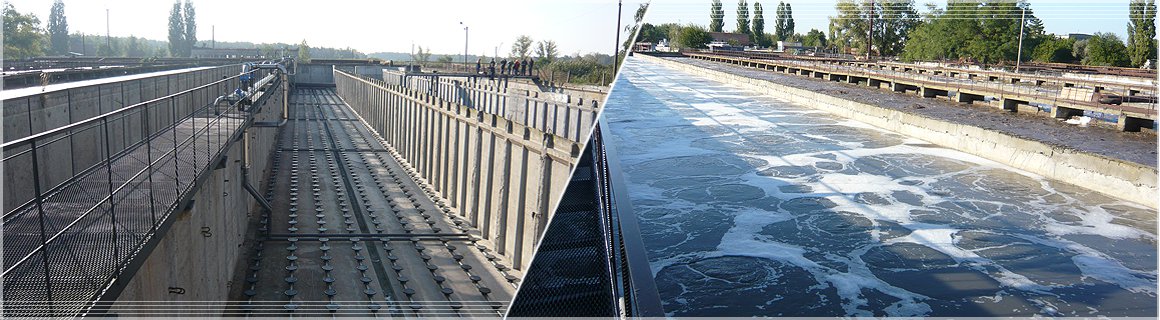

Modular wastewater treatment plant "FLOKFIL" with membrane

Application area

Modular treatment plant "Flokfil" can be used for treatment of wastewater from petroleum, oils, suspended solids and colloidal organic substances with use of flocculation methods, sludge blanket process, flotation and bio filtration.

Description

Capacity of Modular treatment plant "Flokfil» from 1 to 7 m3 / hour

Modular treatment plant "Flokfil» consist of

Flocculator – flotator

Decanting tank

two-stage filter – bio filter with loading the modified polymeric filtering material and biological products, containing microorganism - destructors of oil products, grease and other organic contaminants.

Description of technology

Waste water flows into the flocculation flotator chamber, in which through the dosing tank perfuse flocculent solute (coagulant aid, waste sludge and other). At the same time into flotator is supplied compressed air.

Flocculent solute and compressed air into flotator accelerate and qualitative flotation process, increase productivity and efficiency of modular treatment plant "FLOKFIL".

From flotation block wastewater flows by gravity into the sludge block, where there is a phase separation process.

From flotation block wastewater flows by gravity on two-stage filter – bio filter, filled appropriate synthetic or natural granular filtering material, which also serves for fixation of microorganisms-destructors organic contaminants.

Waste water, treated from the ground mass of contaminants by microorganisms-destructors in the filter-bio filter stage I and filtered from excess biomass in the filter-bio filter stage II, by gravity drained into reservoir of treated water or modular treatment plant "FLOKFIL".

Treatment efficiency at Modular treatment plant "Flokfil" is:

- Oil products - 93 - 98%;

- oils - 97 - 99%;

- Suspended matters - 92 - 98%;

- BOD 5 - 75 - 85%;

- COD - 60 -65%.

Treated water can be discharged in municipal sewerage or reused in industrial processes, carwash, escalator details and etc.